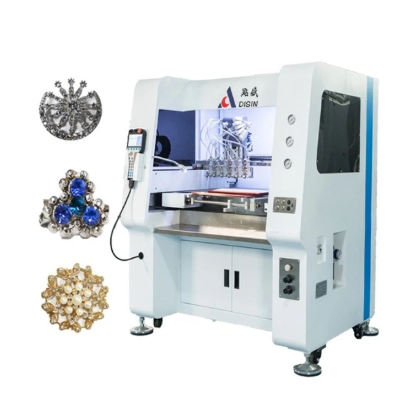

China's Factory Price Automatic Diamond Setting Machines: Revolutionizing Jewelry Production

Xiamen, Fujian Nov 4, 2025 (Issuewire.com) - The art of jewelry making, long defined by meticulous manual craftsmanship, is undergoing a profound transformation. As global demand for high-quality, customized jewelry continues to rise, manufacturers face the dual challenge of scaling production while maintaining the highest standards of precision. This is where the advent of Factory price Automatic Diamond Setting Machine from China is creating a revolution. These intelligent machines are not merely tools; they are comprehensive solutions designed to automate one of the most delicate and labor-intensive processes in jewelry creation: stone setting. By integrating advanced technology with efficient design, they are enabling jewelers and manufacturers to achieve unparalleled speed, accuracy, and cost-effectiveness, democratizing access to high-volume, precise production.

Historically, the process of setting diamonds and other gemstones into a wax model or metal piece was a highly skilled craft, often requiring years of training. Manual stone setting, while yielding beautiful results, is a slow and costly process prone to human error. A single misplaced stone or a slight inconsistency in pressure can compromise the entire piece. The new generation of automatic diamond setting machines from China addresses these challenges head-on. They utilize robotic precision and intelligent vision systems to perform complex tasks, ensuring that every stone is placed with absolute accuracy. This shift from manual to automated processes is a pivotal moment for the jewelry industry, promising to unlock new levels of creativity and efficiency.

The Evolution of Stone Setting in the Jewelry Industry

The jewelry industry has always balanced tradition with innovation. For centuries, techniques for carving, casting, and setting remained largely unchanged. However, with the rise of global commerce and the demand for more affordable, mass-produced luxury items, the need for technological advancement became apparent. Early automation efforts in jewelry were often limited to cutting and polishing. The most intricate part of the processgemstone settingremained stubbornly manual. This created a bottleneck, limiting a manufacturers ability to scale production to meet the needs of a global market.

Today's automatic machines are a direct response to this challenge. They are a culmination of advancements in robotics, machine vision, and software engineering. Unlike manual methods, which are limited by the speed and endurance of the artisan, these machines can work tirelessly at an incredible pace, setting thousands of stones per hour. The rise of these machines has not only increased efficiency but has also made it possible to create designs that would be too complex or time-consuming to execute by hand. They are particularly well-suited for repetitive tasks in mass production, freeing up skilled artisans to focus on unique, high-value, and intricate custom pieces.

Core Features and Advantages of Automatic Diamond Setting Machines

The "factory price" aspect of these machines from China is a major draw, but their true value lies in their cutting-edge features and the benefits they provide to businesses. They are designed to be a complete solution, from material handling to final placement.

- Unrivaled Speed: One of the most significant advantages is speed. A single machine can set thousands of stones per hour, a rate that would require a team of skilled workers to match. For manufacturers, this means shorter lead times and a much higher production capacity.

- Precision and Consistency:Equipped with intelligent vision systems and high-precision servo motors, these machines can place stones with an accuracy of within ±0.02mm. They ensure that every stone is perfectly aligned, with uniform depth and pressure, resulting in a flawless finished product every time.

- Fully Automated Workflow: These machines automate the entire stone-setting process, from picking up the stone from a tray to placing it into the designated spot. Some advanced models can even integrate glue dispensing, combining multiple steps into one seamless operation.

- Versatility: Modern machines are capable of handling a wide range of stone shapes and sizes, from tiny round brilliants to complex marquise cuts. They can be programmed to work on various surfaces, including flat, curved, and intricate 3D wax models, making them suitable for rings, pendants, earrings, and more.

- Cost-Effectiveness: By significantly reducing the reliance on manual labor, these machines dramatically lower production costs. They also minimize material waste and rework, as their precision prevents errors that would otherwise lead to scrapped pieces. This makes them a profitable long-term investment.

The Impact on Modern Manufacturing

More On Starmediaplanet ::

- Mansa AI (MUSA) Introduces Multi-Agent Orchestration Hub for Scalable Web3 Automation

- Harrison H. Lee, MD, DMD, FACS: A Renowned Global Authority in Facial Plastic - Reconstructive Surgery

- BGlam Hair Studio Launches in Indira Nagar, Bangalore, Offering Innovative Hair Solutions for Men and Women

- FoundCall Launches Pet Adoption Partner Program to Help Keep Newly Adopted Pets Safe

- Joy Wood, Recognized by BestAgents.us as a 2025 Top Agent

The adoption of automatic diamond setting machines is not just a technological upgrade; it's a strategic shift that is redefining the business model of jewelry manufacturers. It enables smaller companies to compete with larger ones by achieving high-volume production without a massive labor force. It also allows established brands to streamline their operations, reduce costs, and focus on innovation. This technology also supports the trend of mass customization, allowing for quick changes in design and production runs to cater to individual customer preferences.

Beyond jewelry, this technology is finding applications in other industries that require precise placement of tiny components, such as in the creation of accessories, decorative items, and high-end electronics. The core technologyhigh-speed, high-precision dispensing and placementis a versatile solution for a wide range of manufacturing challenges.

Summary

The rise of automatic diamond-setting machines from China marks a new chapter in the jewelry industry. By offering an unbeatable combination of speed, precision, and affordability, they are enabling manufacturers to overcome traditional production challenges and embrace a future of high-volume, high-quality output. These machines are a testament to the power of intelligent automation and a key to unlocking greater profitability and creative freedom in modern manufacturing.

Media Contact

Youdianman (Xiamen) Intelligent Technology Co., Ltd

Source :Youdianman (Xiamen) Intelligent Technology Co., Ltd

This article was originally published by IssueWire. Read the original article here.